Certain products have an option to add an embossed area to your design. You indicate this by using a special finishing swatch. This swatch is available in our templates, please ask for a copy before starting your design.

How to supply your Embossed elements

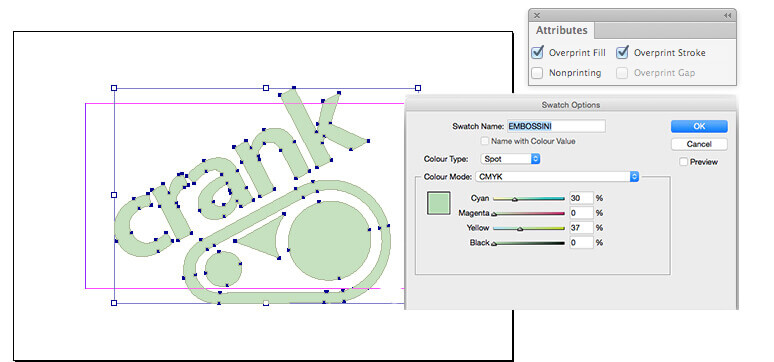

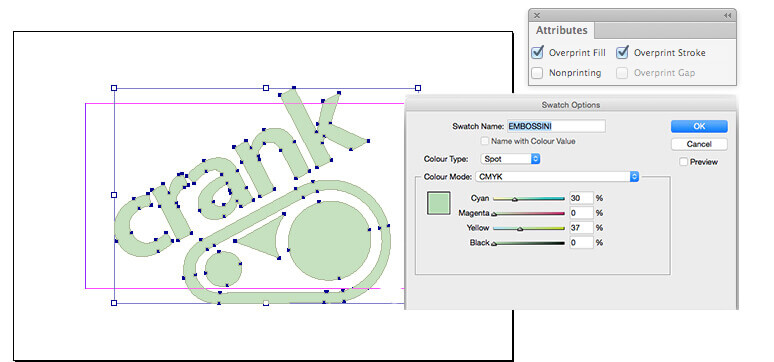

All of our InDesign templates include specific colour swatches for all finishing options or use the instructions below to set up the EMBOSSINI spot colour yourself:

- Create a New Colour Swatch in InDesign.

- Name the swatch 'EMBOSSINI' (must be exact)

- Set Colour Type to Spot

- Set Colour Mode to CMYK

- Colour Make-up is 30% Cyan and 37% Yellow

- Set swatch to Overprint ()

Alternatively, supply your Embossed Vector Shapes filled in 100% K (Black) on page 3 of your PDF and we will adjust the file for you.

How to add the Embossing to your artwork

-

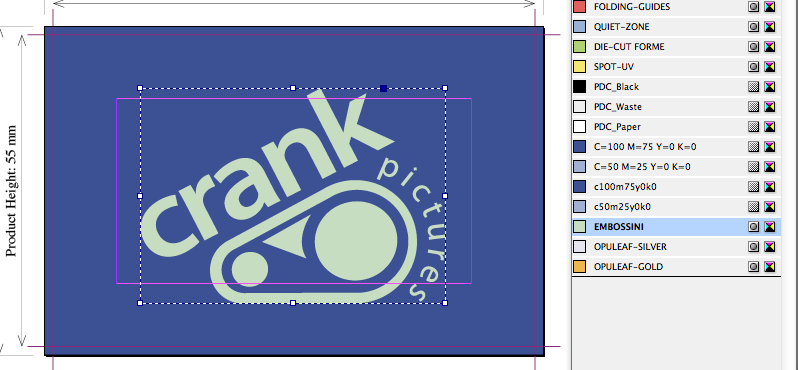

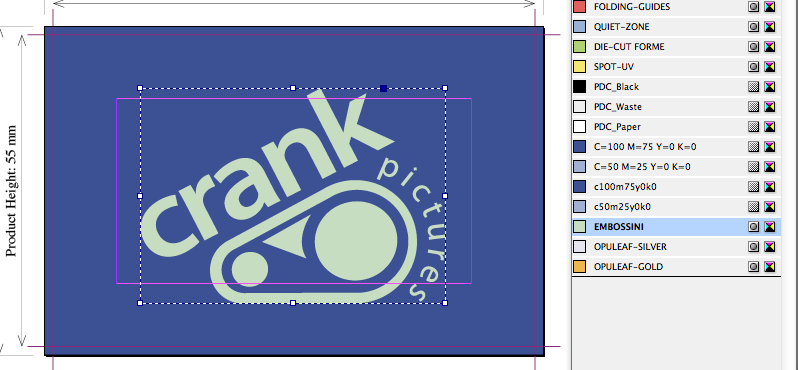

Place the Embossing elements above your using the special EMBOSSINI spot colour swatch. This swatch must remain as a spot colour and must not be adjusted in any way.

-

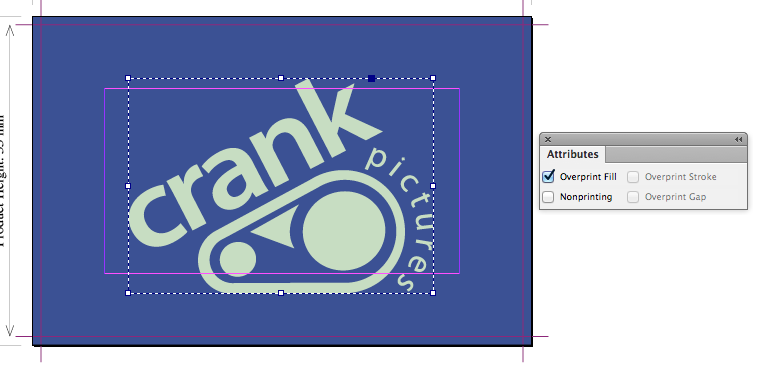

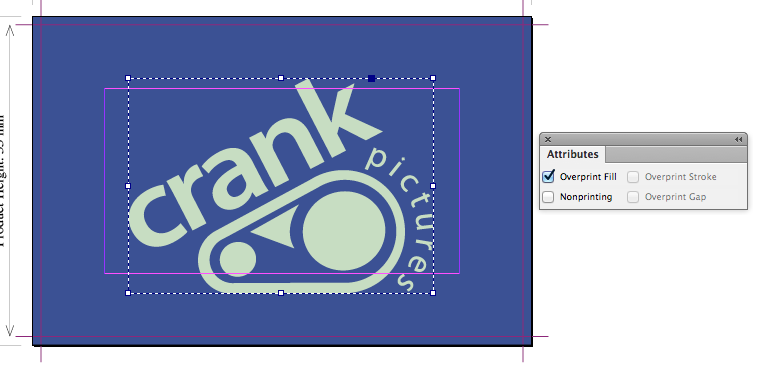

Set the EMBOSSINI elements to Overprint from within your design application.

-

Avoid having areas of embossing bleeding to the edge as chipping, flaking and flattening of the embossed area may occur when the job is guillotined.

-

Only add embossed elements on the front page of your artwork.

Obtaining the EMBOSSINI swatch

This swatch is available in our templates, please ask for a copy before starting your design.

Limitations: Getting the most from Embossing

Design with a little tolerance for mis-registration

The embossing is applied using by applying pressure from the reverse with a die and stretching the fibres of the paper. This means that the registration with print can vary by ±1 mm. This means you should expect the embossed element to move around the page by up to ±1mm.

If you are aiming to cover a printed shape having a hard edge, then the embossed area should overlap the printed edge by 1 mm to allow for any inherent variations in registration.

Don't try to align fine detail

Embossing is not suited to alignment with fine detail, such as small type, or shapes with thin lines.

Our rule of thumb:

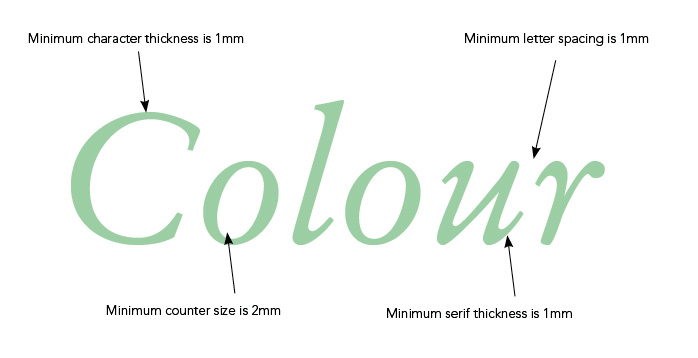

- avoid positive lines thinner than 1 mm, and

- avoid reversed-out lines thinner than 2 mm.

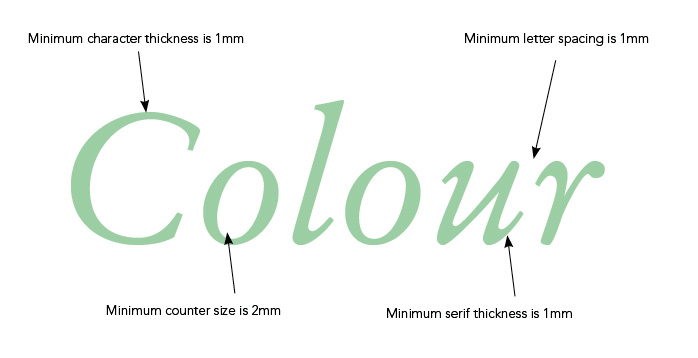

You’ll get best results when you don’t try to match the embossing to printed objects, and instead treat it as a design element in its own right Seperate embossed elements should have a minimum spacing of 1mm. Placing elements too close to each other will result in them becoming one shape and filling in.

Avoid using embossing on small text. Fine fonts, particularly those with serifs or tapered lines do not produce good results. The thinnest part of the font must be 1mm in width.

Avoid large embossed areas over the page edge

Avoid having areas of embossing bleeding to the edge as chipping, flaking and flattening of the embossed area may occur as the job is guillotined.

Vectors only for embossing

Embossed elements must be supplied in vector format; any text shapes to be spot-varnished must be converted to paths/outlines.

Check the minimum thickness on text elements

Remember to:

- avoid positive lines thinner than 1 mm, and

- avoid reversed-out lines thinner than 2 mm.

That includes the counters, stroke width and serifs on fonts.

Solid Embossing only; no tints

Embossing cannot be specified as a gradient or tint, i.e. a changing tint from 100% to 0% over an area of artwork.

Embossing Depth

Embossing depth cannot be accurately measured. It is a process where the finisher determines the depth based on artwork and paper stock, and then has to continually maintain throughout the run. As a rule pressure will be applied to ensure depth will be as deep as possible without cracking the paper. Embossing on printed areas creates more opportunity for cracking and this cracking will be more noticeable on

dark colours.

Be aware that the reverse of the printed item will be "de-bossed", this may distort the design or text on the reverse.

Samples

Printed samples are available, demonstrating how to use embossing. Ask us for your free copies!

Print this page

Print this page